Crystallisation is a key reaction in pharmaceutical and other process sectors.

The combination of two ionic species in solution to form a solid frequently produces a strong change in electrical properties which can be tracked using ITS electrical resistance tomography sensors. Sensor arrays are produced on two different formats:

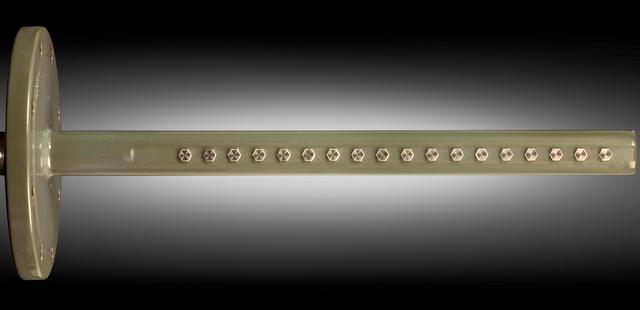

- linear probes – usually inserted as an “intelligent baffle” although it can also be incorporated in the vessel wall. These probes are primarily directed towards changes in reaction conditions at different heights within a vessel. Linear probes can also be used to monitor interface between organic and aqueous phases where anti-solvents are used or phase split is significant.

- circular sensor arrays positioned at different heights within the vessel. These sensors can be incorporated into vessels or retrofitted through cages and provide a more complete picture of reaction conditions.

Tomography sensors can study throughout vessels and provide information on reaction kinetics and concentrations. This can help identify reaction end points more precisely and also yield information on ensuring the right chemical conditions are maintained.

In addition to volumetric information to qualitatively track reactions, process tomography is suited advance chemometric methodologies with data sets available to analyse in MatLab and similar programmes. ITS provides a multiple input / output module which can integrate secondary measurements with tomography data; this is of particular use when applying a temperature ramp and ITS software can adjust for changes in conductivity due to solubility and temperature this providing a basis for focusing directly on reaction kinetics.

Electrical tomography has also been used at different process scales to validate process scale characteristics.